''Bill West'' Switches

Many HP/Agilent/Keysight instruments use a pushbutton switch mechanism generally referred to as the “Bill West” switch, named for the inventor of the mechanism. This switch mechanism is covered by US Patent 4,017,700.

While this switch design is very robust, with so many instruments still in service well beyond their design life, failures do occur. Fortunately, they can almost always be repaired.

Sticky Switches

The most common failure mode is sticky switches. Bill West switches should, if operating normally, have a smooth travel with no perceptible click at all. There's a notable break in their travel, but it is smooth, with no audible click. If such a switch requires greater than normal actuation force and a click is heard and felt, the switch requires service.

This sticking is caused by a lubricant that was applied during the manufacturing process. Over time this lubricant deteriorates and becomes gummy, and causes a spring within the switch mechanism to stick. The audible click is this spring breaking free of the gummy lubricant.

This deteriorated lubricant is easily removed, and in nearly all cases this restores the switch to normal operation.

To repair this failure, remove the board containing the switches from the instrument. Using a pump spray bottle or similar, thoroughly and liberally douse the key mechanisms with 91% (or better) isopropanol. Push each of the buttons several times, then apply another dousing of isopropanol to rinse away any debris from the deteriorated lubricant. Blow off the isopropanol with canned air. Check each switch for proper operation; there should be smooth motion with a moderate break in travel. Reassemble the instrument, and the repair is complete.

No lubricant is actually required on these switches, though if desired, one can apply a very small amount of DeOxit “D” formulation to the PCB contact area underneath each switch mechanism.

Missing Springs

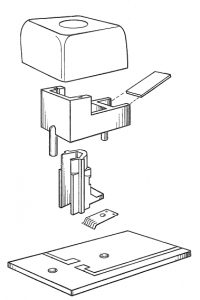

Another failure mode for these switches is missing springs. Each switch mechanism employs a flat sheet of spring steel which can become dislodged from its plastic frame. If this spring is missing, the key will be “flat” and will not return to its unpressed state. Frequently, these springs fall down inside the instrument, sometimes creating an electrical short hazard. However, since they're usually in the front of the instrument, shorts are rare. If you have missing springs, carefully remove the bottom cover of the instrument and search for them in that area.

To install a spring, use fine tweezers to grasp one end of the spring, and feed it through the retaining slot from the back towards the key shaft. Use a pin, pointed probe, or small screwdriver to lift the key shaft end up and into its slot, then push the spring into the notch and release the leaf into the retaining slot.

Referring to the image below; the spring is the flat rectangular object to the right.

If original springs are lost, it may be possible to fabricate them. Anecdotal evidence suggests that steel shim stock may work. The spring dimensions are 0.588“L x 0.140” x 0.002“.